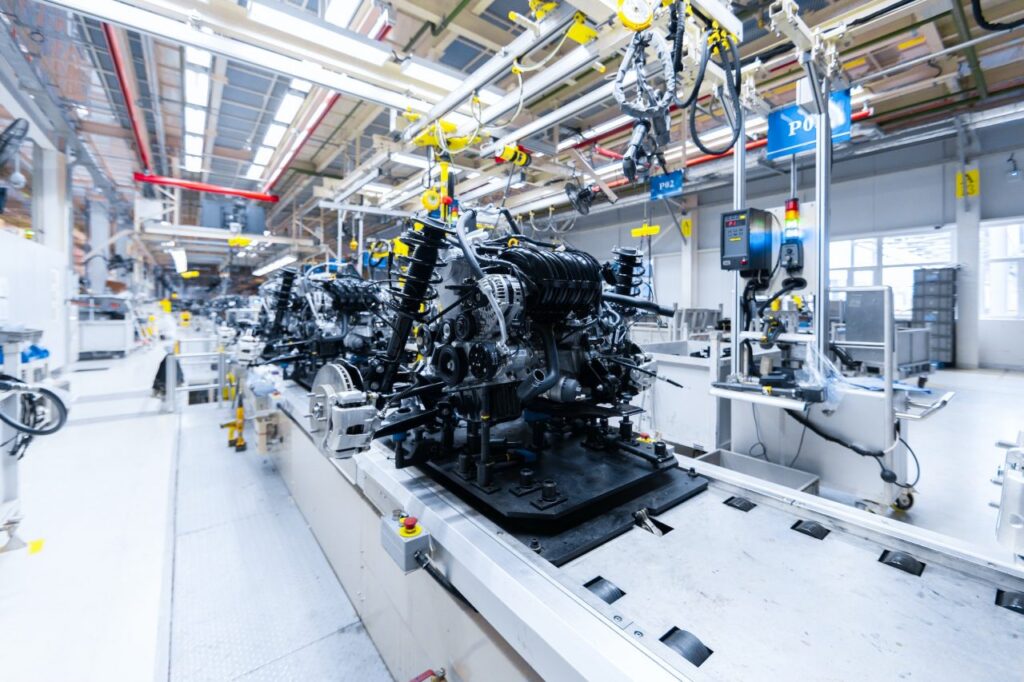

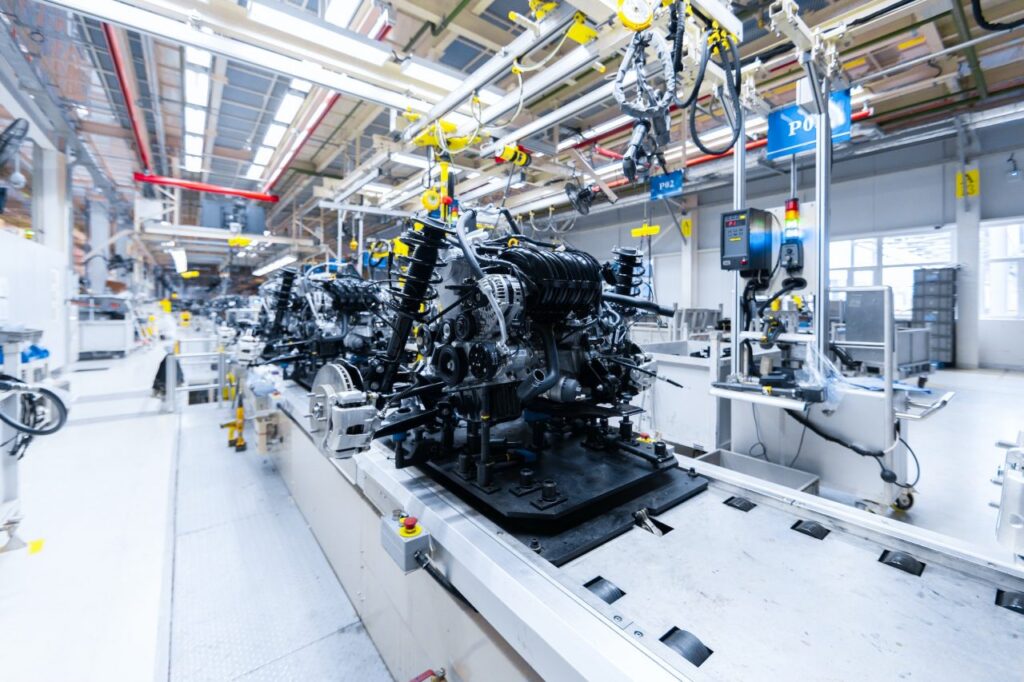

At Elina Engineering, our Pickling and Degreasing Lines are engineered to deliver the highest standard of surface preparation for metal coils. Whether you’re removing oxides, mill scale, or residual oils, our systems ensure clean, defect-free metal—ready for downstream processing such as cold rolling, galvanizing, coating, or stamping.

Built with precision and sustainability in mind, our solutions help manufacturers maintain product integrity, improve finish quality, and enhance line efficiency.

Our pickling lines use acid solutions and mechanical systems to remove scale and impurities from hot-rolled metal surfaces, making them suitable for further processing.

Key Features:

Continuous or push-pull configurations

Efficient acid circulation and recovery systems

Integrated scale breakers and brush units

Rinsing and drying sections for clean, dry output

PLC-controlled automation and safety features

Applications:

Cold rolling feedstock

Galvanizing and coating preparation

Automotive, appliance, and construction materials

Benefits:

Superior surface cleanliness

Reduced environmental impact with acid recycling

High-speed operation and consistent output

Seamless integration with other processing lines

Our degreasing systems remove oils, lubricants, and particulate contamination from metal strips using alkaline or electrolytic methods combined with multi-stage rinsing and brushing.

Key Features:

Alkaline spray and immersion cleaning

Electrolytic degreasing (optional for enhanced cleaning)

Energy-efficient heating and drying

Advanced filtration and chemical dosing

Compact layout for easy plant integration

Applications:

Pre-treatment before coating, painting, or rolling

Carbon steel, stainless steel, and non-ferrous strips

Precision component manufacturing

Benefits:

Consistent cleaning quality at high speeds

Improved coating adhesion and surface finish

Easy maintenance and low chemical consumption

Reliable performance under continuous operation

Customized lines for your material and production volume

Smart automation and real-time monitoring systems

Eco-friendly design with optimized chemical usage

Complete lifecycle support—design, delivery, and service

Ensure the highest quality output by starting with the cleanest input.