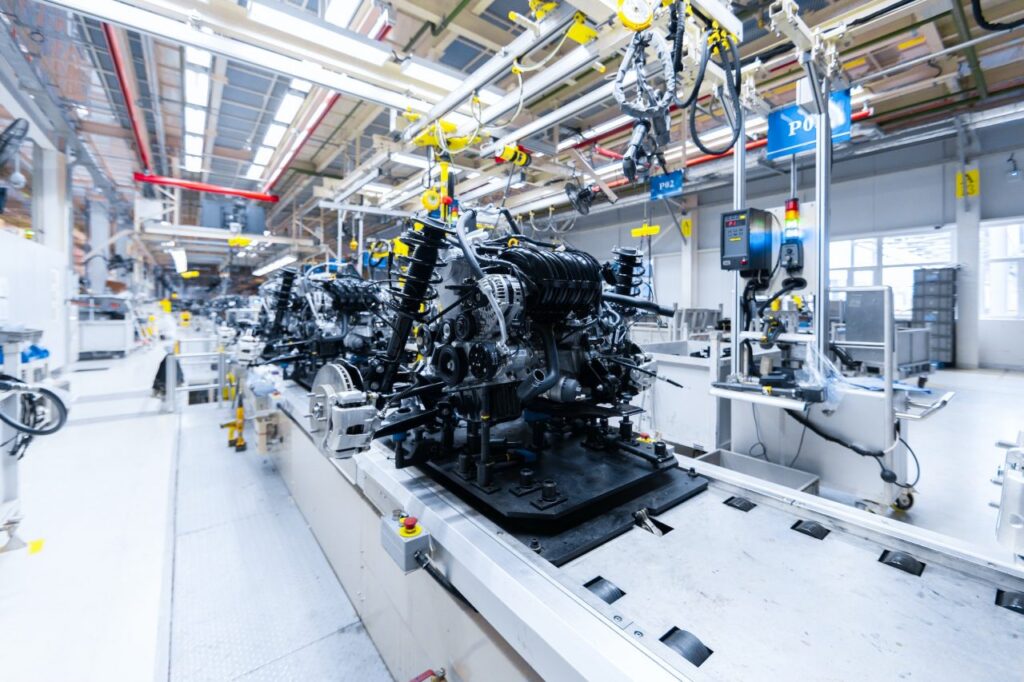

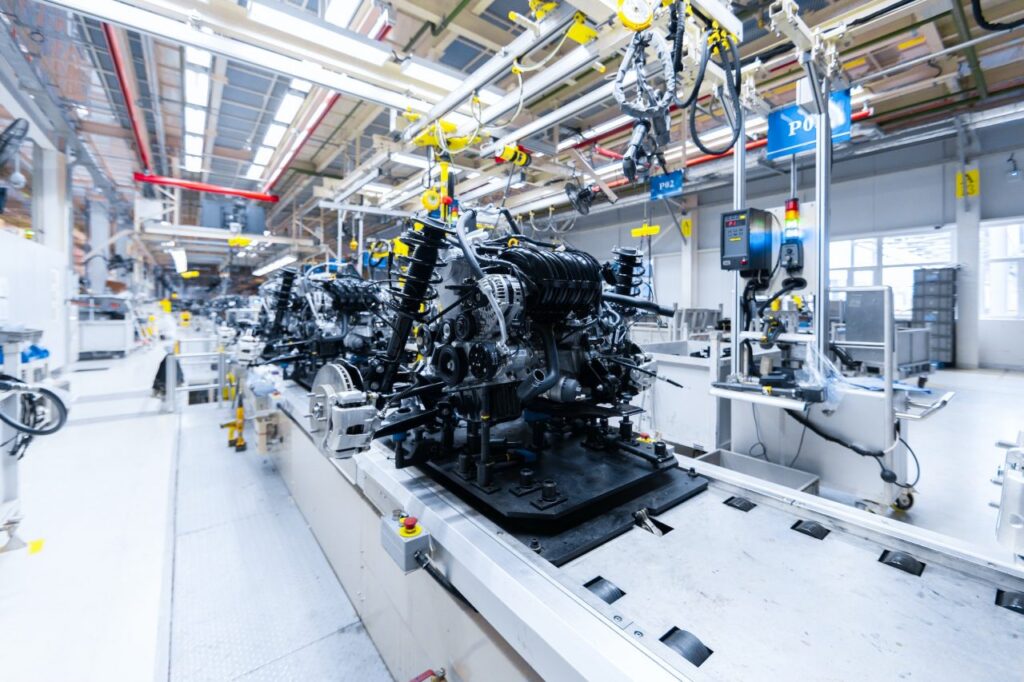

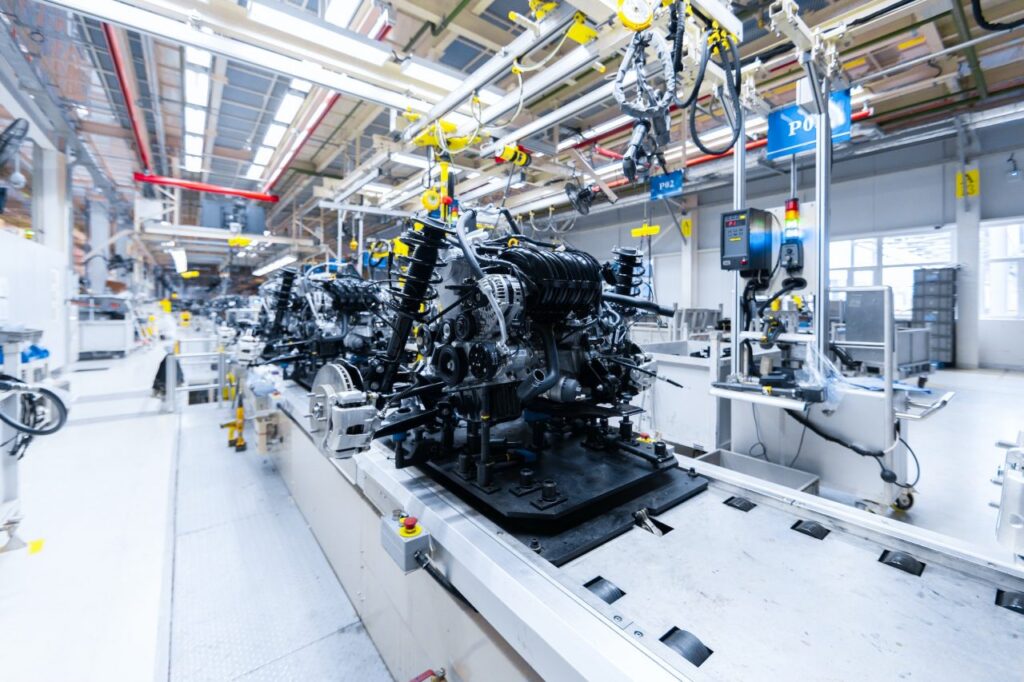

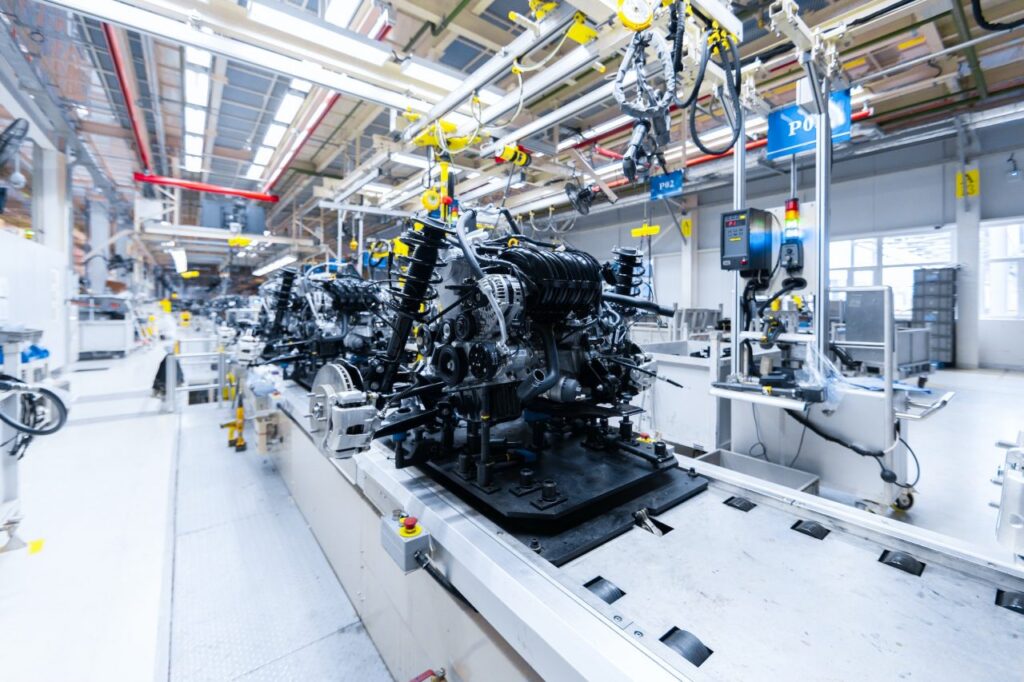

At Elina Engineering, we offer a complete range of coil processing lines engineered to deliver precise, efficient, and high-speed transformation of metal coils into ready-to-use forms. Whether you’re slitting, leveling, cutting to length, or preparing coils for further processing, our systems are built for productivity, accuracy, and long-term performance.

From carbon steel to stainless steel and non-ferrous alloys, our solutions meet the complex needs of industries such as automotive, construction, appliances, and general manufacturing.

Our slitting lines are designed to cut wide coils into narrower strips with clean edges and minimal burrs, ready for downstream processes.

Key Features:

Quick tooling changeovers

Advanced strip tension control

High-speed, high-accuracy operation

Optional scrap handling and recoiling units

Applications:

Electrical enclosures, tube & pipe manufacturing, stamped components

Our CTL lines offer high-performance straightening, feeding, shearing, and stacking of coil materials into precision-length sheets.

Key Features:

Servo-driven feeding for tight tolerances

Precision leveling for excellent flatness

Automated stacking for smooth operation

Versatile for various coil widths and thicknesses

Ideal For:

Roofing sheets, automotive blanks, appliance panels

Our tension levelling systems eliminate coil set, buckles, and waviness, delivering perfectly flat strips for cosmetic and high-performance applications.

Benefits:

Multi-roll leveling technology

Advanced strip tension control

Suitable for thin and high-strength materials

Real-time monitoring and control

Integrated cleaning systems that remove rust, oxides, and oils—preparing the strip for coating, painting, or cold rolling.

Advantages:

Eco-efficient acid recovery

Superior strip cleanliness

Smooth integration with other lines

Custom-built for your plant layout and production requirements

Designed for speed, accuracy, and uptime

Seamless integration with rolling mills and finishing lines

Backed by expert commissioning and lifelong support

Discover how our coil processing systems can streamline your production line.